The International Copper Association Australia (ICAA) commissioned the University of Sydney’s Warren Centre for Advanced Engineering to develop a strategic roadmap to achieve a ‘zero-emission copper mine of the future.’

In a 68-page report, the Warren Centre explains that, typically, greenhouse gas emissions through the copper production process are associated with the consumption of fuel in the mining and materials transport processes and indirect emissions from electrical energy use in extractive and beneficiation processes.

“In general, the energy consumption in the primary copper process is dominated by the earlier stages of beneficiation. This is due to the high energy demand requirement to crush and grind ore. Within the mining process loading and hauling, blasting, and ventilation (in the case of underground mining) all consume a higher proportion of energy to other aspects of the mining process,” the document states.

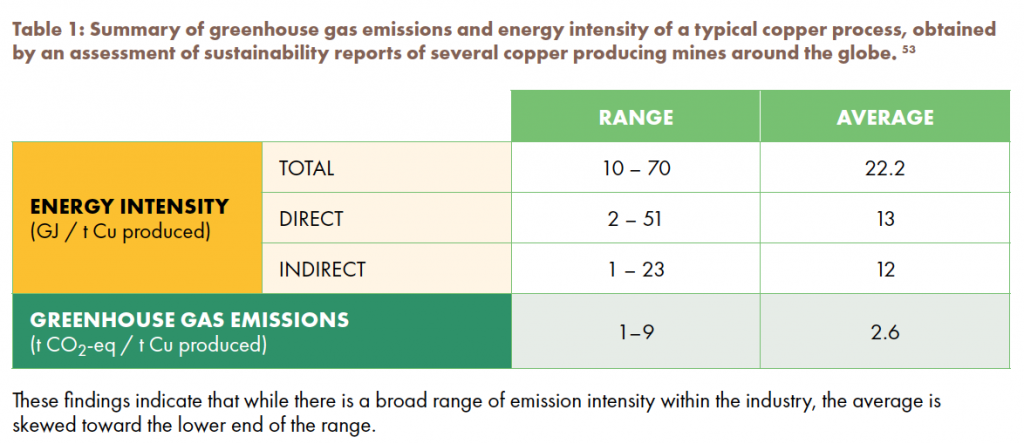

Based on a literature review, the report concludes that the average energy intensity and GHG intensity is 2.6 t CO2-eq per tonne of copper produced, a figure that varies by location, extraction methodology, and ore grades.

To move towards a greener mine, the report says that one key strategy is to increase transparency and reporting.

To achieve this, copper miners are asked to account for direct emissions, such as those from sources that are owned and controlled by companies, including onsite power generation; indirect emissions, which are those released into the atmosphere due to the consumption of an energy commodity, for example, emissions from the generation of purchased electricity to enable the copper production process; and finally, all other emissions that are generated indirectly as a result of activities from sources that are not owned or controlled by the company, like the emissions as a consequence of the use of the sold copper cathode for the manufacture of semi-fabricated products.

“Measurements of greenhouse gases are recorded relative to carbon dioxide equivalence (CO2-eq). For instance, a manufacturing or processing company emitting 1 tonne of methane into the atmosphere has the same global warming potential as emitting 25 tonnes of carbon dioxide. Hence, 1 tonne of methane would be expressed as 25 tonnes of carbon dioxide equivalence,” the report reads.

According to the document, emissions can be reported in absolute terms (total CO2-equivalent emissions, or CO2- eq) and intensity terms (CO2-eq per unit). Absolute measurements, however, should be combined with efficiency metrics to understand performance at a company or sector level.

The review recognizes that there are challenges associated with reaching the zero-emission goal, particularly how to achieve emission reduction outcomes while maximizing economic resource productivity at the industrial level, rather than simply offsetting or abating emissions associated with a given product cycle.

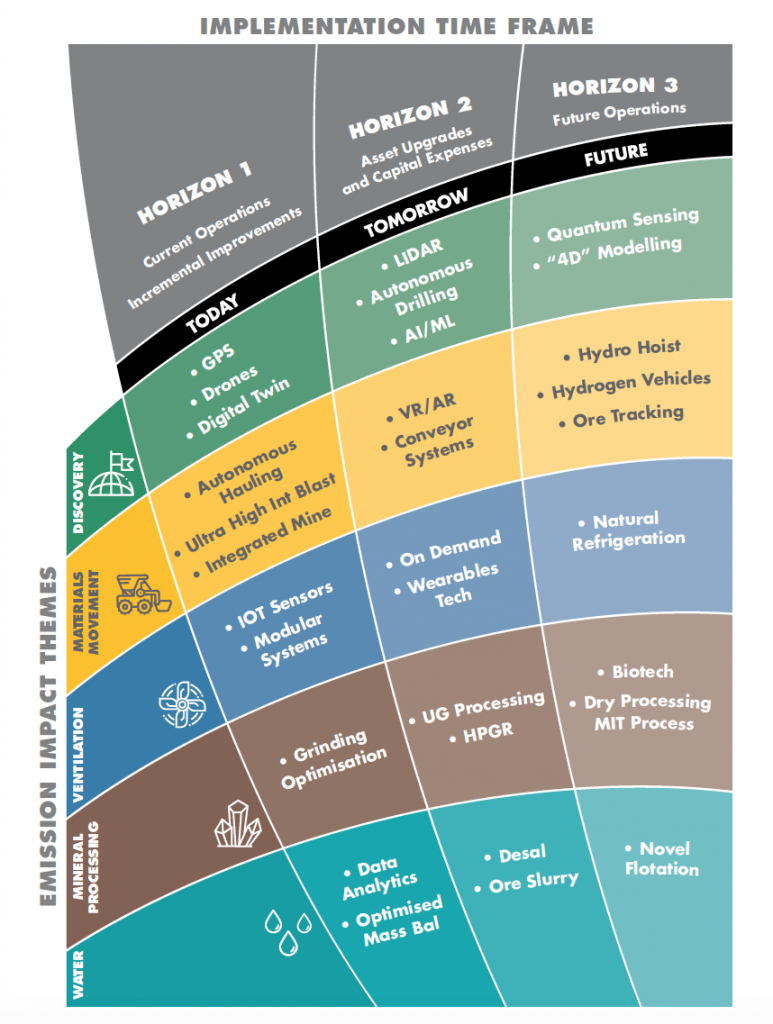

Besides transparent reporting, copper miners are encouraged to reach out to existing innovative mining equipment, technology and services (METS) businesses, which can be an important source of new ideas to address emission reduction pathways in the short and medium-term.

According to the Warren Centre, METS can be key players for finding ways to reduce both costs and emissions through innovation, a path that should also include government and research institutions.

“Applying advanced technologies at the discovery and exploration stage of the mining cycle will enable the development of robust ore-deposit identification and exploration models to improve the likelihood of detection of high-grade deposits in greenfield and brownfield sites. Advanced technologies can optimize attractive host rock settings and subsequent future ore recovery,” the document reads.

In a series of tables, the report presents specific segments of the discovery phase that can be addressed from existing or in-development innovations with the goal of reducing emissions. The tables are also presented for processes related to material movement, ventilation, mineral processing and water usage.

In summary, when it comes to material movement, the Warren Centre’s proposal focuses on the need to further advances in the electrification of mining systems and the transition to automation in all aspects of the mining and material movement process. In particular, it highlights the importance of making use of incremental technologies that are able to deliver technical efficiencies with improved asset availability, reduced maintenance requirements, extended mine life, enhanced productivity and reduced emission outcomes.

For ventilation, the document points to shifts in technology, particularly autonomous systems that are allowing for the deployment of fewer people underground, which means that ventilation systems can be transitioned to be on-demand while power requirements are optimized.

When it comes to mineral processing, targeted innovation efforts that should continue to be explored are technologies to improve crushing and grinding efficiencies, separation and concentrate drying, optimization of processing performance, in addition to measurement technologies to interconnect systems across the whole of plant operations and dry processing technologies.

There is also encouragement to adopt in-situ recovery mechanisms as they have the potential to be a low-impact and selective mining option because they imply the recovery of valuable metals from ore deposits by the circulation of fluid underground and the recovery of the valuable metal from the fluid at the surface for further processing.

Addressing water usage, the report proposes a number of strategies that range from site stormwater capture, treatment and discharge to building slurry pipelines. However, the main focus is on industrial-scale desalination (reverse osmosis) technologies or the use of membrane technology to remove salts and other contaminants from water.

Even though the Centre recognizes that desalinization requires elevated energy inputs, the report also states that the growth in renewable technology is proving to be an effective offset mechanism to the high-energy intensive operations of desalination plants.

Fonte: Mining.com